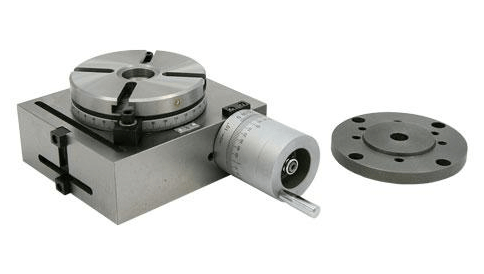

Rotary Table Tips

If you are involved in metalworking, you will agree with me that it is one industry that requires a lot of ? precision and stability, in order to get the best precise results. Getting the precision, accuracy, and stability is dependent on the equipment used to achieve the objective, and this is where the rotary table comes in. A rotary table is a precision device that is used to aid precision positioning when handling metalworking task. Performing various rotary table tasks usually involves the operator being able to effectively cut and drill around a fixed axis and at exact intervals. Furthermore, it is also possible to add indexing with rotary tables that are fitted with dividing tables that create the avenue to facilitate seamless operations when handling metalworking activities.

In order to get the best out of the rotary table, it is important that you get the set up of the table right, or it could affect the operations. However, there are some tips that can help you get the best out of your rotary table, and thus help boost your productivity. If you want that much-needed stability, accuracy, and precision, then you may need to pay attention to the following tips:

Table Setup

The importance of getting the table set up right, cannot be overemphasized, hence, in order to get it right, there are two steps to go about this, in order to help you get the best out of the whole process:

- First Step

It is essential that you ascertain that the device is centered properly on the table, and in order for you to do properly, you should have the rotary table clamped down on to the mill table, and then if you have an indicol indicator holder, you may need to place it on the spindle of the mill, and then locate a round feature on the table to indicate on. You may try indicating on the round boss of the plate milling fixture located somewhere above, or on the hole of the center. Perform a spin of the table, and then keep bumping the part in till the indicator stops moving.

- Second Step

Look for the rotation’s center located, under the spindle of the mill, or better still apply the XY table handwheels. Apply the indicol, as an indicator of the circular feature you intend to have placed under the spindle, then use the spindle to turn the spindle around, and in the process have the handwheels adjusted till the indicator is not able to move again and corresponds with the spindle position.

Rounding Fixture

If you intend to affix a rounding fixture, it is best that you use a rotary table that has a chuck mounted, as that is an ideal part to have a rounding fixture properly set up.

Do not Allow for Overrun When Using the Rotary Table for Rounding with End Holes

If you are performing a partial rounding by having a part cranked about when using the rotary table, there is the tendency to make mistakes, and go overboard. In order to get it right, you may need to bring some drilling to the endpoints, in order to be able to point where you want the stopping point to be.

Apply a Collet Fixture on the Rotary Table

If you use a Blake indicator, this part would be much faster, and if you do not have a Blake indicator or your mill cannot have one on it, then you need to make use of the ER collet feature, and apply it to your rotary table, and you need to do it such that when installed, the collet’s axis is properly aligned with the axis of the table.

If you intend to get the best out of the rotary table, then you should try the tips, and your productivity will experience some boost. Furthermore, if you are looking to accessorize the rotary table, it is imperative that you only use accessories that you trust, in order not to hamper your activities as a result of using an unfamiliar accessory. There are several applications of the rotary table, including the manufacturing industry, for inspections, and even video and photography.